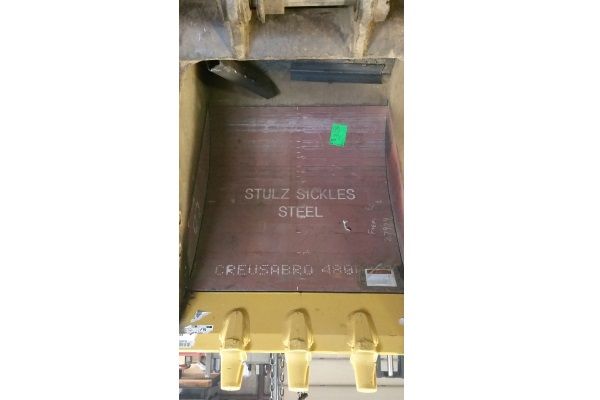

Creusabro 4800 & 8000

Stuls-Sickles Manganese Steel

Creusabro 4800 & 8000 Manganese Steel

Transformation Induced by Plasticity (TRIP Effect).

Significantly Better Wear Resistance

Due to its initial structure not fully martensite (a mix of martensite, bainite and retained austenite), STULZ CREUSABRO has the ability to work-harden when submitted to local plastic deformation induces a surface hardening phenomenon by transformation of retained austenite into fresh and very hard martensite while the material remains ductile underneath, makes it a most effective to withstand both abrasion and heavy impact in service.

Lifetime is increased

Against conventional water quenched steels, wear resistance of STULZ- CREUSABRO grades is increased and maintenance costs reduced.

Usually, choice of material is made on a price and hardness basis. However, users have to face difficulties of wear parts replacement. One must therefore add to the material price both the costs of maintenance and production downtime, in order to establish the true cost-effectiveness of a material.

Resistance to high temperature is guaranteed

Which allows the use of STULZ-CREUSABRO grades in high conditions (≤ 450ºC - 840ºF) such as met in Cement Works, Foundries, Steel Industry, Asphalt Plants...